The wooden beam rotted, buckled and split. How to repair a damaged beam

Wooden beams and roof-ceiling soffits are the most commonly affected in old houses because wood is a natural material with a shorter lifespan compared to other durable materials.

Wood can rot, split and warp, not only from age, but also from compromised installation techniques, including a lack of necessary ventilation or neglecting to waterproof the beam support point on a masonry wall.

In this article, we will explore a couple of practical and effective ways to repair and restore a damaged timber beam without having to replace the entire beam.

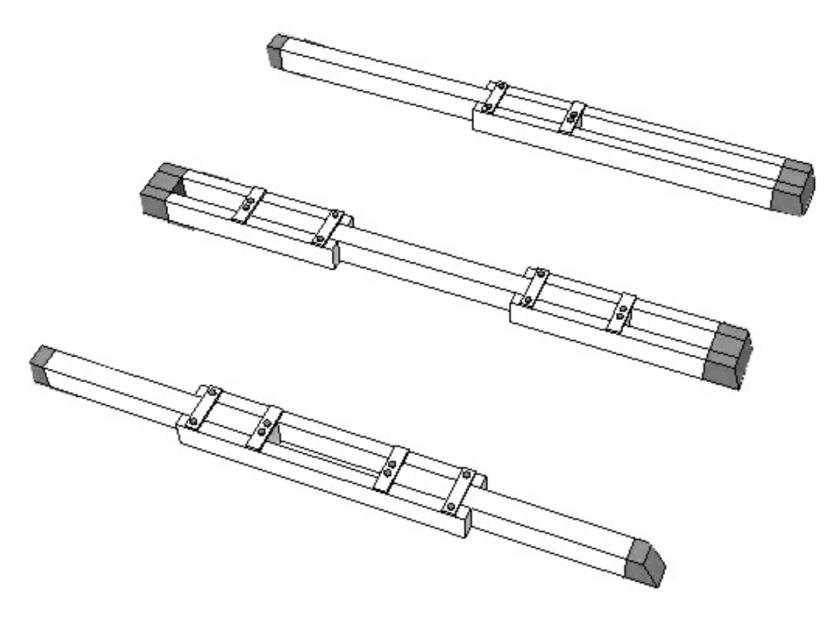

Beam joint reinforcement with trusses

The jointing method is used in all damaged areas of the beam (e.g. the support ends or the middle of the beam) and in all cases of damage to the beam, whether it is through spalling, splitting or rotting.

The idea is simple: the undamaged part of the beam is supported from below by a support stand and the damaged part of the beam is cut out. This is followed by side-joists made of new, sound timber, but fixed not from the sides to the existing beam, but from the top through the use of metal plates – corners or troughs, using screws. Illustrated examples can be seen in the following diagrams:

The advantage of the pinch method is that the deflection of the beam is adjustable with nuts and there is no need to cut and align the deflections or to add various inserts to align the deflected beam to the existing slab.

The truss system can be assembled on site, the cost is very low and the system has excellent load-bearing capacity. The stiffness of the repaired beam is 20-30% higher than that of a solid beam. In addition, the length of the beam can be increased using this method.

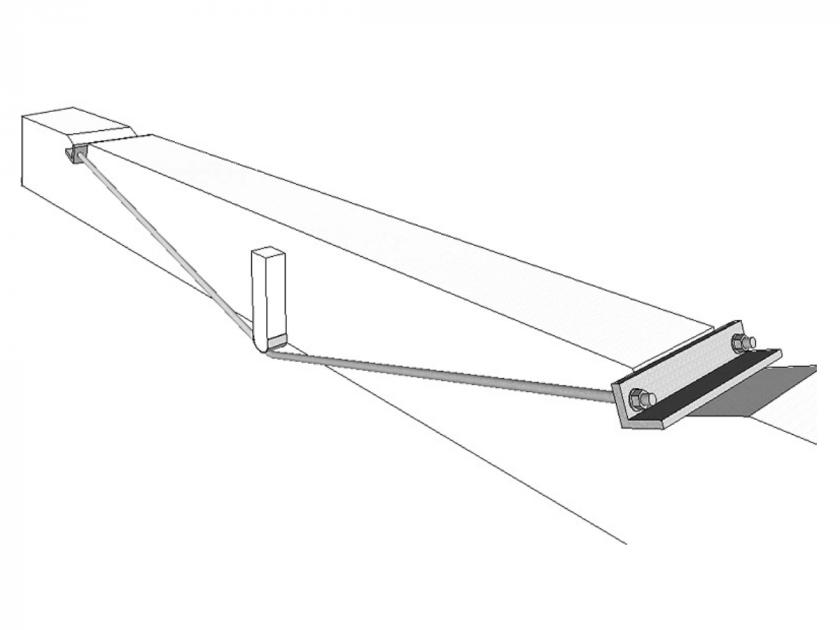

Strengthened Steel templates for a spanning beam

The steel tensioning method has proved to be a good method for eliminating girder deflections and deformations. Before using prestressed steel tendons, it is important to support the structure from below with a braced stand to maximise the deflection of the beam.

Then, at the point of greatest deflection of the beam, the wooden lashing points are tightened firmly on both sides with a steel strip (minimum 2 mm thick) at the lower ends.

Near the supporting ends of the beam, cut-outs shall be made in which the metal support angles shall be inserted. The angles are pierced with holes through which a reinforcing steel tensioning strap with threads at the ends is subsequently tensioned. The diameter of the steel template is 30 mm.

The threaded ends of the template shall be tightened with nuts until the overlapping beam has straightened and is horizontal. See diagram:

If the beam is later bent again, then the tensioning nuts can be re-tightened to tighten the tensioning more tightly and straighten the beam.