Is natural milk "suitable" for breastfeeding?

This may seem like a strange question in traditional livestock farming, but if we are talking about dairy breeding heifers and the most appropriate feed composition for them, we can consider. Not to mention the challenges of ensuring uniformity in the composition of natural milk, the main problem is the fat content of natural milk. For the future dairy cow, the most relevant is protein for muscle building. Also very important are minerals and vitamins, which are too scarce in natural milk to meet the needs of a modern calf. And this is about „healthy“ milk suitable for human consumption. Let's not even talk about the milk from cows with mastitis, which is still being fed to calves on Lithuanian farms.

Despite the fact that mother's milk is supposed to be the best feed for a calf, on a dairy farm calves are usually not fed their mother's milk because they are given a mixture of milk from all cows. One of the main challenges for farms feeding calves on natural milk is to ensure consistency of composition and quality.

The following are the advantages of milk replacers compared to natural milk.

Nutritional content:

• Consistent feed composition (independent of the cow's lactation period, seasonality and physiological condition).

• Less fat than natural milk and therefore less chance of forage-borne diarrhoea.

• Targeted to the needs of calves (fat, protein, minerals...)

Economy:

• Milk can be sold to a buying company, which is much more profitable these days

• Optimises calf growth and produces the best dairy cow on the farm.

Security:

• Reduces the risk of feeding inappropriate feed to calves (milk from cows with mastitis with antibiotics)

• Easier protection against infectious diseases that are transmitted to offspring of mothers (e.g. paratuberculosis)

• Convenient storage, significantly longer shelf life

Simplicity:

• More flexible feeding schedule (not linked to milking time)

• Easier organisation of staff schedules

The economic advantage of milk substitutes is clear, given the current purchase prices for raw milk. The average farm-gate price for June 2025 was 499.91 €/tonne of milk (according to the MAFF), which would be 0.49991 €/litre of raw milk. To prepare 1 litre of milk substitute at a powder price of, say, 2,60 &euro/kg, costs only 0,35 &euro. The difference is clear.

How do I choose a milk replacer for my calf?

Today, the availability of milk replacers on the market is so vast that it is becoming increasingly difficult for farmers to choose the right one for their calves. To make this easier, here are some important criteria to consider when choosing.

What is calf milk replacer?

It is a cow's milk substitute that must provide the energy and protein requirements for optimal growth of the calf. This is achieved through the proper selection of raw materials for the production of the product, and through ensuring the production technology. The raw materials must have certain characteristics:

• Nutritional and palatability

• Physical (solubility, colour, particle size)

• Consistency of supply and price

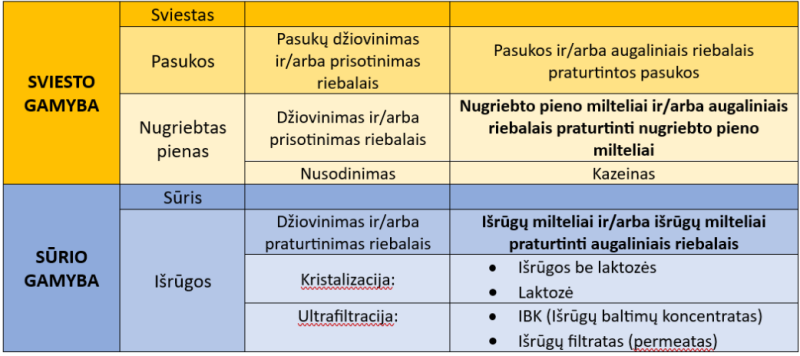

How are the raw materials for the milk processing process obtained?

The process has two main branches:

Cheese production

• Butter production

Thus, the milk processing process produces two main raw materials used for the production of milk substitutes: whey powder and skimmed milk powder.

Two types of milk substitutes are commonly produced:

• Based on skimmed milk powder

• Based on whey milk powder

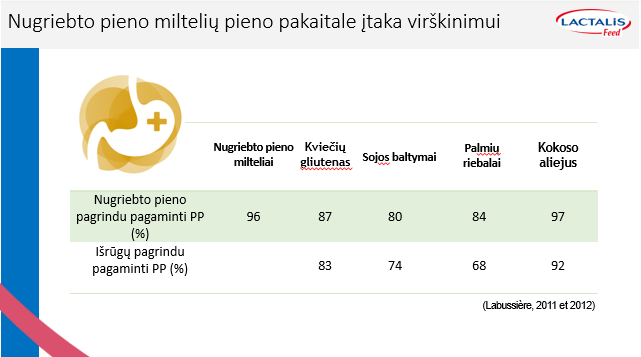

Depending on the type of milk replacer fed to the calves, the digestive process in the intestine differs. Differences in digestion time lead to differences in nutrient absorption.

When a calf is fed a whey-based milk replacer, the milk replacer that enters its intestine is transformed into a yoghurt-like mass. This consistency moves through the intestines relatively quickly (digestion takes about 2 hours).

When a milk replacer containing more than 35% high quality skimmed milk powder is fed to the calf, the milk protein casein coagulates in the calf's spleen and a casein clot (cheese) is formed. This results in slower digestion (about 6 hours) and better absorption of not only the protein but also other nutrients, the percentages of which are given in Table 2. The higher the percentage of skimmed-milk powder in the milk replacer, the better the result.

Influence of pasteurisation technology on the quality of raw materials

Even if a milk substitute is based on skimmed milk powder, its quality can vary considerably due to the amount of skimmed milk powder and the different pasteurisation technologies used, of which there are three:

• Low-temperature pasteurisation: 72–80 °C for 15–30 seconds.

• Mid-temperature pasteurisation: 85 ° C for 1 minute or 90 –105 ° C for 30 seconds.

• High temperature pasteurisation: 90 ° C for 5 minutes, 120 ° C for 1 minute or 135 ° C for 30 seconds.

The differences between these technologies determine the effect of temperature on milk proteins, i.e. their solubility, digestibility and biological activity.

High temperature technology denatures a relatively high proportion of the proteins, reduces their biological activity and makes them less soluble. With low temperature pasteurisation, the degree of protein denaturation is much lower, the digestibility and bioactivity remain high & the proteins react with enzymes as in natural milk and dissolve well.

Therefore, in the manufacture of milk substitutes using skimmed milk powder, it is not only the quantity of this raw material that is important, but also the production technology used.

Analytical ingredients

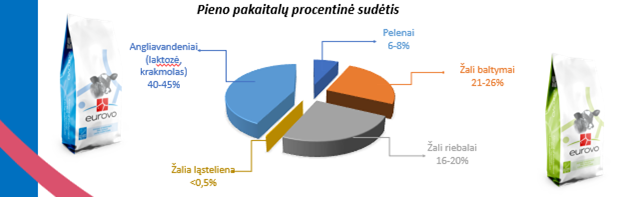

Figure 3 provides a percentage chart of the analytical ingredients in milk substitutes, which is more or less typical for most milk substitutes produced.

It is really important to know not only the percentage composition of the nutrients in a milk substitute, but also which raw materials are used to achieve the appropriate composition:

• Protein: The source of protein in milk substitutes is raw materials from dairy processing and plant proteins (soy protein, gluten). In the case of ultra-high quality milk substitutes, no vegetable protein is used at all, and of course the price of such substitutes is correspondingly higher.

• Fats: The most commonly used fats in milk substitutes are palm fat, coconut oil (very easily digested and absorbed) and, to a lesser extent, rapeseed oil (unsuitable for use in substitutes for newborn calves). Animal fats can be used but are less commonly used due to their higher cost.

• Fibre: Fibre content is very important. Newborn calves should have no or as little fibre as possible (0.00 % to 0.10 %). Please note that if the milk replacer contains protein of plant origin, the fibre, even if low, must be indicated in the composition. So-called zero fibre can only be present in milk substitutes that are produced without the use of plant protein.

• Pelenium:

• Macronutrients.

• Micronutrients.

• Vitamins: A, D, E, B, C, K3.

• Probiotics: e.g. Bacillus licheniformis, Bacillus subtilis.

• Antioxidants: e.g. Proviox 50.Important fact: When selecting a different milk replacer, be sure to check its density by weighing the measuring container containing the powder (Figure 4), as the density of different milk replacers, even from different products from the same manufacturer, can vary by up to 20%, and the density of the same milk replacer, from different lots, can also vary slightly. This is very important, because if you change to a milk replacer with a lower density, your calf will simply not get the nutrients it is entitled to according to the feeding recommendations.

Why is a higher daily calf weight a good thing?

• The higher the daily weight, the faster the calf reaches weaning weight and the less milk replacer is used.

• Adapts earlier to concentrates.

• Reaching weaning weight sooner reduces the age at first calving.

• 100 g more daily weight leads to 135–155 litres more milk yield in first lactation. Two studies by Soberon and Van Amburgh (2013) and Gersinger (2016) found a correlation between daily weight and production in the first lactation. The main reason for this is better mammary gland development.

• The importance of intensive feeding and good protein uptake is evident.

When is it time to wean the calf?

One indicator is the presence of BHB (beta-hydroxybutyrate) in the calf's blood. This is an important indicator that the large rumen is beginning to function and if the calf is deficient in glucose after the cessation of watering, it will be able to provide itself with energy by eating.

The large rumen is active and the liver produces small amounts of BHB. At a level of 0.2 mmol/l in the calf's blood, the point is reached where the calf can be weaned. Of course, a simpler indicator is when the calf eats 2 kg of concentrated feed per day or reaches the corresponding weight of 100–110 kg.

So, to sum up, I would like to emphasise that all animals on the farm are very important, but I would single out the calves because they are the future of the farm.

These are the animals that should not be skimped on, indeed, they should be given the best possible conditions, fed only the highest quality feed and given the best possible care. For what is invested today will be paid back later.

If you have any questions, please do not hesitate to contact: Virginijus Kanapė, +370 649 76082